Professional Design 12″ Long Locking Pliers for Cape Town Manufacturer

Short Description:

Product Detail

Product Tags

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to provide you with excellent service of processing for Professional Design 12″ Long Locking Pliers for Cape Town Manufacturer, We are sincere and open. We look forward to your visit and establishing trustworthy and long-term standing relationship.

Basic Information

■Model Number: RL-DLQ016

Additional Information

■Material: A3# steel (Q235) or 45# steel

■Size: 12”

■Surface Treatment: Nickel-plated, Zinc-plated, Black Oxide, Electrophoresis

■Heat Treatment: Optional

■Package: Blister Card, Suction Card, Tie Card, Double Blister Card

■OEM: Acceptable

■HS Code: 8203200000

■Samples: For FREE

■Delivery Time: Always 30 working days depending on the order quantity

■Packing: By standard cartons

Product Description

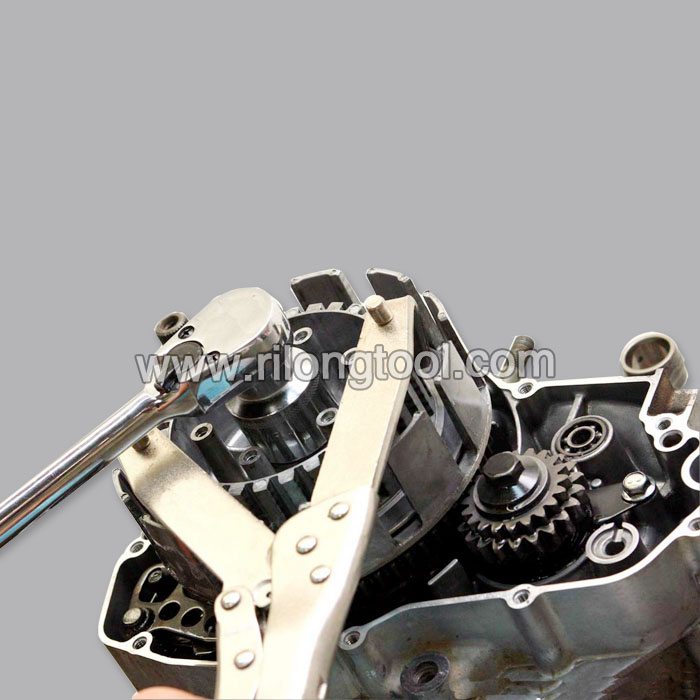

■Mainly used for clamping parts to rivet, weld, grind and so on, which is characterized by the powerful clamp force produced by the jaw. It can lock tight so that the parts won’t fetch away. Besides, jaws have a lot of levels to adjust for the use of different thickness of parts, and it also can be used as a wrench.

■Flexible using, long life and good tenacity.

■The screw tuning button can give the best clamp size easily.

Product Image

Fully insulated 7 inch Inlec VDE pliers tested to 1000V and certified to EN 60900. Suitable for working on live circuits of 1kV AC and 1.5kV DC. Heat treated CrNi steel forging or durability. Soft grip handles for user comfort.

- 3 year warranty

More information: https://www.manvtools.com/index.php?route=product/product&path=60&product_id=114

A word of caution: When done properly with healthy batteries, this method of emergency welding is safe. However, there are dozens of ways to screw this up and cause property damage and injury. Attempt this at your own risk! I accept no liability for what you decide to do.

This is a short video demonstrating how to weld steel using a pair of batteries and a set of jumper cables. I’ve used this method out on the trail lots of times and it comes in handy when you find yourself with broken parts out in the middle of nowhere!

While I would not recommend using this as your primary shop welder, it does work well in an emergency situation. Adding a few pounds of welding rod to your toolbox is excellent insurance against a long walk home!

Common questions that seem to keep popping up:

What electrode did I use in the video?

I believe that I used 1/8″ 6011 in the video, although the electrode choice depends on the material you intend to weld. I’ve found that 6011 or 7018 works well for most trail repairs

will it destroy the batteries?

No; I’m certain that it isn’t GOOD for them, but when done properly, this method of welding draws roughly 150 amps…similar to a starter motor or a lightly loaded winch motor. A typical 8000lb winch under full load can approach 500 amps; WAY more than this welding method. From the battery’s perspective, there is little difference between trying to start your vehicle for 15 seconds or welding for 15 seconds. One of the batteries in my Samurai is the same 9 year old battery that has completed dozens of trail repairs.

Will the batteries explode?

I’m sure there is probably some calculable (albeit minimal) risk. It is rare, but faulty batteries have been known to explode when placed under a heavy load. Batteries offgas very little under discharge (there may be some H2 and O2 gas left in the cells from the last charge cycle, but the concentrations are so low there is almost no risk. The discharge cycle does produce a small amount of aqueous hydrogen, but this remains in the electrolyte and does not leave the battery). The hydrogen and oxygen gas they produce under charge IS flammable and can explode; so don’t charge the batteries and then immediately weld next to them. As the discharge rate is similar to an engine starting, there is no more risk of the battery exploding during welding than there is during an engine startup. When was the last time you heard of a battery explosion that WASN’T related to somebody hooking up jumper cables backward or some other kind of operator error? Don’t let a fear of a battery explosion keep you from using this technique to complete an emergency trailside repair. I would be foolish to say there is no risk, but the risk IS minimal.

What have you repaired on the trail with this method?

1 Samurai tie rod end, one beadlock bolt (got ripped out of the wheel, causing a large leak), one XJ tie rod, one air intake horn on a VW diesel engine, one Land Cruiser frame and steering box, one off-road trailer frame, two different lower shock mounts, one spring plate, an upper wishbone for the rear axle on a Suzuki Sidekick, and I have used it about a dozen or more times for quick “band aid” repairs around my property. I have watched other people use this quite a number of times, and a friend of mine even built an entire rollcage using this method.