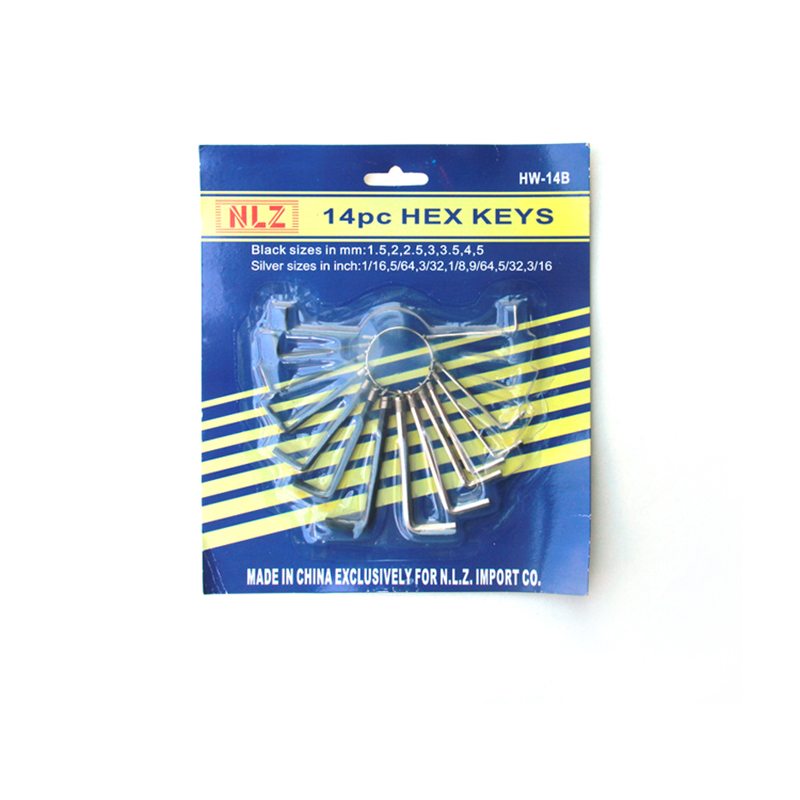

Popular Design for 14-PCS Hex Key Sets packaged by spring ring Manufacturer in Australia

Short Description:

Product Detail

Product Tags

Our company since its inception, always regards product quality as enterprise life, continuously improve production technology, improve product quality and continuously strengthen enterprise total quality management, in strict accordance with the national standard ISO 9001:2000 for Popular Design for 14-PCS Hex Key Sets packaged by spring ring Manufacturer in Australia, We are confident to make great achievements in the future. We are looking forward to becoming one of your most reliable suppliers.

Basic Information

■Model Number: RL-NLJ003A

Additional Information

■Material: 45# Carbon Steel

■Size: 1/16″-3/8″, 1.5mm-10mm

■Surface Treatment: Zinc-plated + Black Oxide

■Heat Treatment: Optional

■Package: Spring Ring + Suction Card

■OEM: Acceptable

■HS Code: 8204110000

■Samples: For FREE

■Delivery Time: Always 30 working days depending on the order quantity

■Packing: By standard cartons

Product Description

■Ningbo Rilong Hardware Tools Factory can provide various kinds of Hex Key with different sizes and packages.

Product Image

Toro model 20072, six years old. Would not start and after checking out YouTube videos, I determined coil was shot. Lots of great videos on YouTube on how to troubleshoot lawnmowers and engine systems.

The old coil would not produce spark. Checked around town here and price for new coil was way too high ($60). I bought mine online for $22.09 with free shipping but you can find them for under 20.00. Part came from Kansas and took just 3 days. Type of “coil” that can be used on this model is “Stens 440-505 Solid State Module”.

When I received the coil I noticed it was missing one rivet on the laminated core. To avoid delays in fixing lawnmower I decided to repair coil rather than returning it to Amazon for a replacement. I hunted up a steel tube rivet and made a “washer” out of a small steel nut by grinding it thinner, clamped laminations with vise grip pliers, and then hammered down the tube rivet end using a 7.5 mm doming punch (dapping punch). It worked great ![]()

Make sure you plug the wire back on the coil terminal (bottom side of installed coil on mower) after installing your new coil. Don’t torque the screws too tight on the mower as it has aluminum parts. You can set the coil gap using a plastic card (not embossed one).

Hope video will help you on your project in getting your mower running again. Take care and good luck on your mower troubleshooting ![]() William

William