Factory supplied Hay Knife Sets to

Short Description:

Product Detail

Product Tags

"Sincerity, Innovation, Rigorousness, and Efficiency" is the persistent conception of our company for the long-term to develop together with customers for mutual reciprocity and mutual benefit for Factory supplied Hay Knife Sets to, Create Values,Serving Customer!" is the aim we pursue. We sincerely hope that all customers will establish long term and mutually beneficial cooperation with us.If you wish to get more details about our company, Please contact with us now.

Basic Information

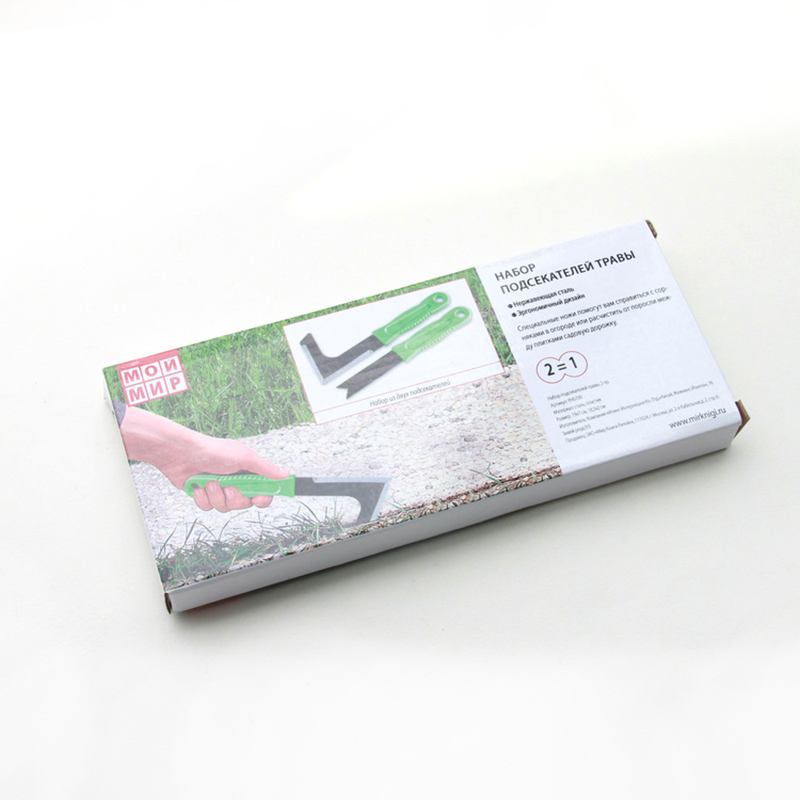

■Model Number: RL-GCD003

Additional Information

■Material: Carbon Steel

■Size: 8”

■Surface Treatment: Black Oxide, Painting

■Handle: Injection molding

■Color: Optional

■Package: Suction Card

■OEM: Acceptable

■Samples: For FREE

■Delivery Time: Always 30 working days depending on the order quantity

■Packing: By standard cartons

Product Description

■Used to remove the weeds and stem leaf in the cracks.

Product Image

Contributing editor Christopher Schwarz demonstrates the holding power of blacksmith-made holdfasts.

FIND BELOW the tools we use, board repair help forum, tutoring & repair services, and parts sites. Thank you for supporting us by using the links below!

✖ TOOLS SUGGESTED:

● Soldering Iron: https://amzn.to/2cKkMyO

● Preferred tip: https://amzn.to/2d5MgPn

● Micro Soldering Pencil: https://amzn.to/2d5MWUP

● Micro soldering tip: https://amzn.to/2qUSFDh

● Hot Air station: https://amzn.to/2d5M7Lw

● Microscope & LED light: https://amzn.to/2iLrE16 https://amzn.to/2nzfPT2

● CHEAP Microscope: https://amzn.to/2rTlHbj

● Flux: https://bit.ly/2cYIx7t

● Solder paste: https://bit.ly/2epK1JE

● Tweezers: https://amzn.to/2d5NBpi

● On-Screen multimeter: https://amzn.to/2qG0Bse Setup guide: https://bit.ly/2pMarYQ Probes: https://amzn.to/2ssqr51

● Fume Extractor: https://amzn.to/2d5MGoD

● Solder: https://amzn.to/2cKkxUp

● Crest CP500D Ultrasonic cleaner: https://bit.ly/2pnKL5h

● Branson EC cleaning fluid: https://amzn.to/2cKlBrp

● Jumper wire THIN: https://amzn.to/2eqF5T7 THICK: https://amzn.to/2eAJ5AU

● Nitrile gloves: https://amzn.to/2iUfumS

Bench PSU: Agilent 6542